- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

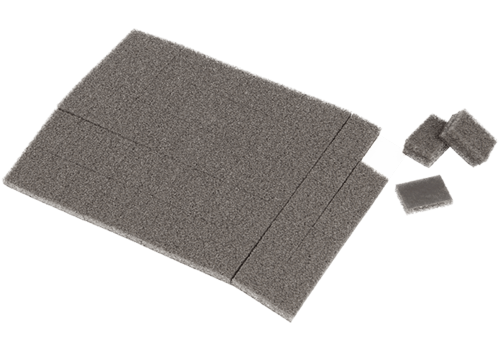

Electrically conductive foam

- Home

- EMI shielding gaskets solutions

- EMI shielding gaskets

- Electrically conductive foam

Conductive foam offers an innovative approach to traditional shielding and grounding by providing X, Y, and Z-axis conductivity, which enhances the shielding effectiveness required to meet the increasing microprocessor speeds of today’s computer, telecommunications and aerospace equipment.

This conductive foam is made of polyurethane foam plated with copper and nickel. Compression is 25% to 75%. The temperature range is between -10 and 85 °C.

The material will return close to normal height when released. The foam is coated with conductive polyurethane to protect it from environmental influences and to prevent burrs when cutting. It is RoHS compliant.

Conductive Foam is designed for low-cycling applications such as input/output (I/O) shielding and other non-shear standard connectors. Rectangular strips are available for perimeter gasketing applications.

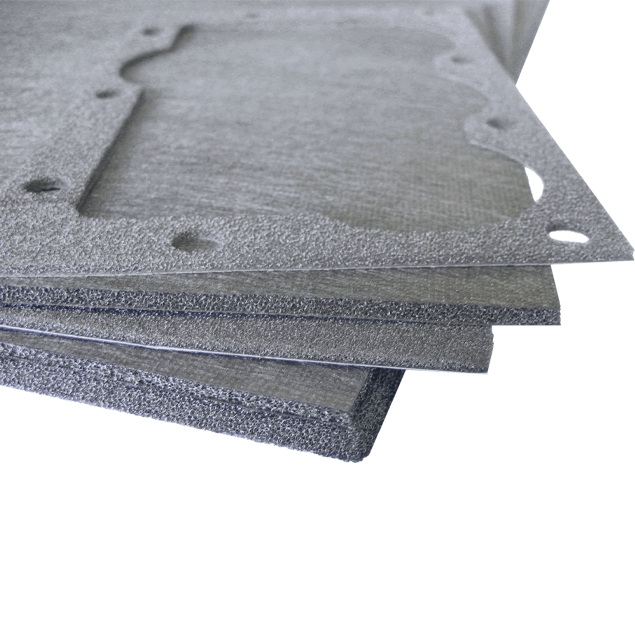

Product build-up

For reference only, not to scale

Technical data

| Item | Data |

|---|---|

| Material thickness (other sizes on request) |

1, 1.5, 2, 2.2, 3.0, 3.5 or 5 mm (other sizes on request) |

| Colour | Gray |

| Width | Max. 950 (mm) |

| Length | Depending on thickness material 50 meters max. |

| Adhesive strength (gf/25mm) | >1.000 |

| Surface resistance (Ω/sq) | 0.2 |

| Top-bottom resistance (Ω/in2) | 0.2 |

| Restriction of Hazardous Substances (RoHS) | Compliant |

| Temperature range °C | -10 to 85 |

Shielding performance

Please note: These values are measured under laboratory conditions. Results may vary in other situations; please read our Guarantee.

Characteristics:

- Thicknesses of 1, 1.5, 2, 2.2, 3.0, 3.5 and 5 mm in 950 mm roll width

- Thicknesses of 0.3 mm in 300 mm roll width

- Several layers can be joined together for thickness, on request

- Excellent electric conductivity throughout the material

- Excellent electromagnetic shielding effect

- High workability due to adhesion

- Easy die cutting, kiss cutting and slitting

Applications

- Mobile phone

- Noise filter core

- Cable tray

- Shielded rooms

Material specifications

- Mesh: woven polyester, copper, and nickel coated

- Conductive foam: polyurethane foam (copper and nickel coated)

- PSA: acrylic ester polyol copolymer + nickel powder

- PU coating: polymer resin (polyurethane)

- Release liner: CP paper avg 150 μm

Benefits and options

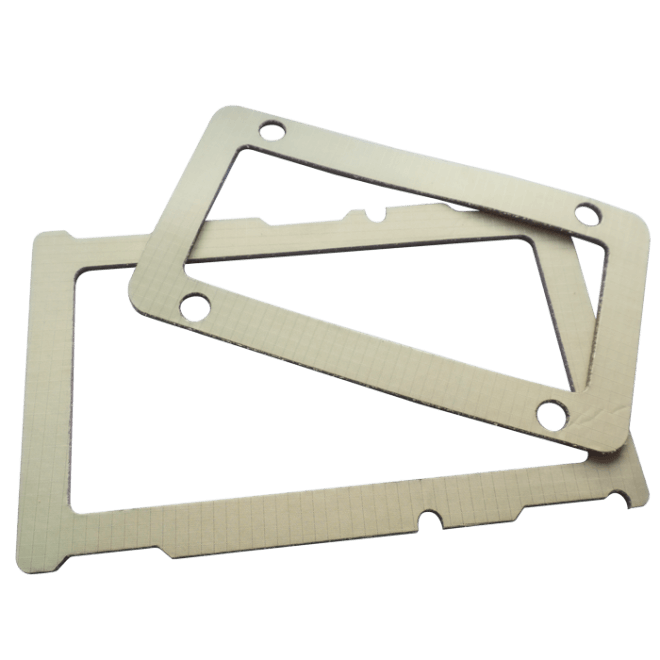

- Supplied as sheets, strips or die-cuts

- Reinforced with woven fabric on 1 or 2 sides

- Nickel/copper metalization

- X-Y-Z axis conductivity

- Tolerance of ± 0.1 mm

- I/O static applications/gasket replacement

Shielding effectiveness 100 Mhz - 1 GHz

- 1.5 mm thickness, 80 dB - 83 dB

- 3.5 mm thickness, 80 dB - 103 dB

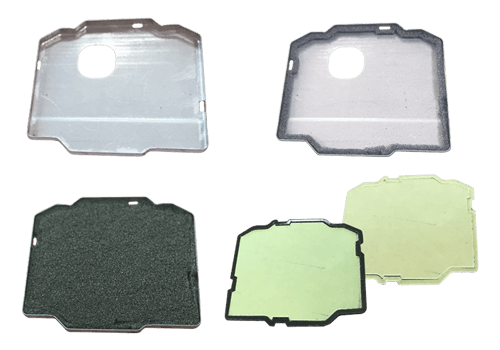

Product example of 5770 Conductive foam in use

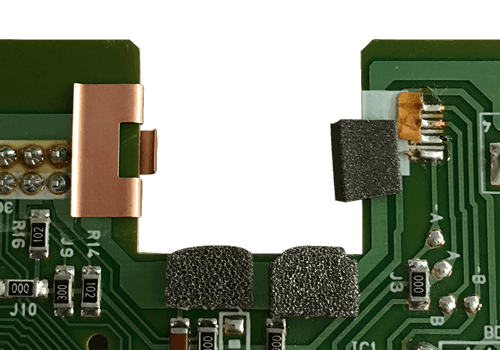

Product example of 5770 Conductive foam placed on a PCB

Conductive foam kiss cut according to customer's requirements. The conductive foam pieces can be easily removed from the release liner and be stuck into place with the electrically conductive adhesive.